In the dynamic landscape of the oil and gas industry, the demand for efficient and reliable flow control solutions has never been greater. Among these, plug valves have emerged as vital components known for their durability and excellent sealing capabilities. According to a recent market analysis by Grand View Research, the global valve market is expected to reach USD 100 billion by 2025, with plug valves being a significant contributor due to their versatility in handling high-pressure and temperature conditions.

Choosing the right plug valve can drastically improve system performance and reduce maintenance costs, making it essential for industry professionals to understand the various types available. This blog will explore the potential of plug valves in oil and gas applications and provide insights on how to select the most suitable option for your operational needs.

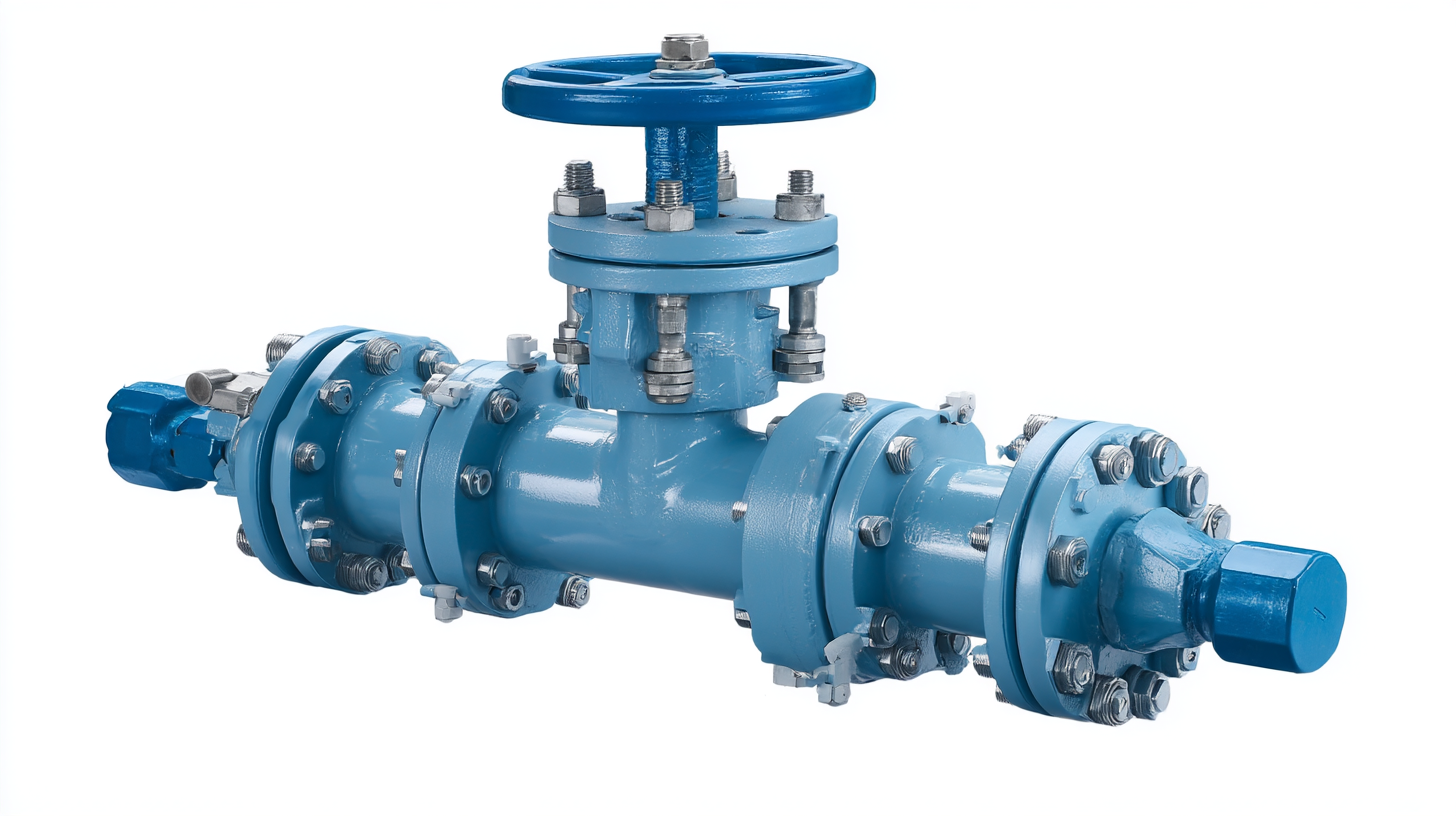

In the oil and gas industry, plug valves play a crucial role in ensuring the safe and efficient flow of fluids. These valves are designed to provide a tight seal and reliable operation, making them ideal for applications where leakage could lead to catastrophic failures or environmental hazards. Their simple design allows for quick operation and maintenance, which is particularly important in the fast-paced world of oil and gas operations. Understanding the importance of plug valves can help operators optimize their systems for both performance and safety.

Choosing the right plug valve is essential for meeting the specific needs of various applications. Factors such as pressure, temperature, and the nature of the fluid being transported must be considered to ensure compatibility and longevity. Additionally, the right material selection can prevent corrosion and wear, further extending the valve's service life. By investing time in understanding the critical role plug valves play in oil and gas applications, companies can enhance operational efficiency and uphold high safety standards across their processes.

| Feature | Description | Application Area | Material Options | Temperature Range |

|---|---|---|---|---|

| Flow Control | Provides precise flow regulation and isolation | Upstream Production | Carbon Steel, Stainless Steel | -20°C to 200°C |

| Leakage Prevention | Designed to minimize leakage even under high pressure | Midstream Transportation | Brass, PVC | -10°C to 150°C |

| Ease of Maintenance | Simplified design for easy repair and replacement | Downstream Refining | Aluminum, Composite Materials | -30°C to 180°C |

| Durability | Robust construction to withstand harsh environments | Oil Well Injection | Nylon Reinforced, High-Temperature Alloys | -40°C to 250°C |

When it comes to selecting the best plug valves for oil and gas applications, understanding the key features that define high-quality options is crucial for optimal performance. One of the most important characteristics to consider is the material construction. High-quality plug valves are typically made from durable materials like stainless steel or high-grade alloys, providing resistance to corrosion and wear, essential for handling the aggressive nature of oil and gas.

When selecting the right plug valve for oil and gas applications, several critical criteria must be considered to ensure operational efficiency and safety. Primarily, the valve's pressure and temperature rating should align with the specific conditions of the application. According to a report by the Global Valve Market 2021, approximately 55% of valve failures can be attributed to inadequate pressure ratings, emphasizing the need for thorough evaluation in the selection process.

Another essential factor is the material of the valve, which must be resistant to corrosive environments typical in oil and gas operations. A study published by the American Society of Mechanical Engineers notes that improper material choices account for roughly 30% of maintenance costs in the industry. Thus, choosing materials such as stainless steel or specialized alloys can significantly impact the longevity and reliability of the plug valve.

Lastly, the ease of maintenance and operation cannot be overlooked. Reports indicate that companies investing in user-friendly designs can reduce downtime by as much as 25%, thereby improving overall productivity. By assessing these criteria—pressure and temperature ratings, material suitability, and maintenance ease—industry professionals can better equip their processes with plug valves that meet their specific operational needs, ultimately unlocking their full potential.

Chinese manufacturing has become a cornerstone of the global valve production landscape, especially in the oil and gas sector. According to a report by MarketsandMarkets, the global valve market is expected to reach $80.3 billion by 2026, fueled by increasing exploration and production activities. China plays a significant role in this growth, accounting for over 30% of the world’s valve production by volume while striving to meet international standards. This dominance is largely attributed to advancements in manufacturing technology and a skilled workforce, continuously pushing the envelope on quality and efficiency.

Moreover, Chinese manufacturers are increasingly focusing on research and development to enhance their product offerings, including plug valves. A study published by Mordor Intelligence highlights that the demand for high-performance valves in oil and gas applications is on the rise, driven by the need for reliable and efficient equipment in harsh environments. As a result, Chinese firms are not only producing a vast array of valves but are also improving their specifications to ensure they meet specific industry requirements, positioning themselves as trusted suppliers in the global market.

The oil and gas industry is constantly evolving, and with it, the technology behind plug valves is seeing significant advancements. Future trends in plug valve technology promise enhanced performance to meet the demanding requirements of modern operations. Innovations such as automated controls, improved sealing materials, and smart technology integration are expected to redefine the functionality of plug valves. These advancements not only improve safety and efficiency but also minimize downtime, ultimately leading to cost savings for operators.

The oil and gas industry is constantly evolving, and with it, the technology behind plug valves is seeing significant advancements. Future trends in plug valve technology promise enhanced performance to meet the demanding requirements of modern operations. Innovations such as automated controls, improved sealing materials, and smart technology integration are expected to redefine the functionality of plug valves. These advancements not only improve safety and efficiency but also minimize downtime, ultimately leading to cost savings for operators.

Moreover, the shift towards sustainable practices in oil and gas is influencing the development of eco-friendly plug valve solutions. Manufacturers are focusing on reducing the environmental impact of these valves by utilizing recyclable materials and designs that minimize leakage. The push for greater energy efficiency is also driving the research and development of plug valves that can handle higher pressures and temperatures while maintaining reliable performance. As these trends continue to shape the landscape, choosing the right plug valve will be crucial in optimizing operational efficiency and aligning with future regulatory standards.