In the realm of industrial applications, selecting the right pressure valve is crucial for ensuring operational efficiency and safety. With a diverse range of pressure valves available, each designed to handle specific pressures, temperatures, and fluid types, understanding their unique characteristics and suitable applications is imperative for making an informed decision. This blog will explore the various types of pressure valves, detailing their features and applications to help you identify the ideal solution for your particular needs.

Additionally, we will provide practical guidance on how to evaluate and choose the best pressure valve, equipping you with the knowledge necessary to enhance your industrial processes.

Additionally, we will provide practical guidance on how to evaluate and choose the best pressure valve, equipping you with the knowledge necessary to enhance your industrial processes.

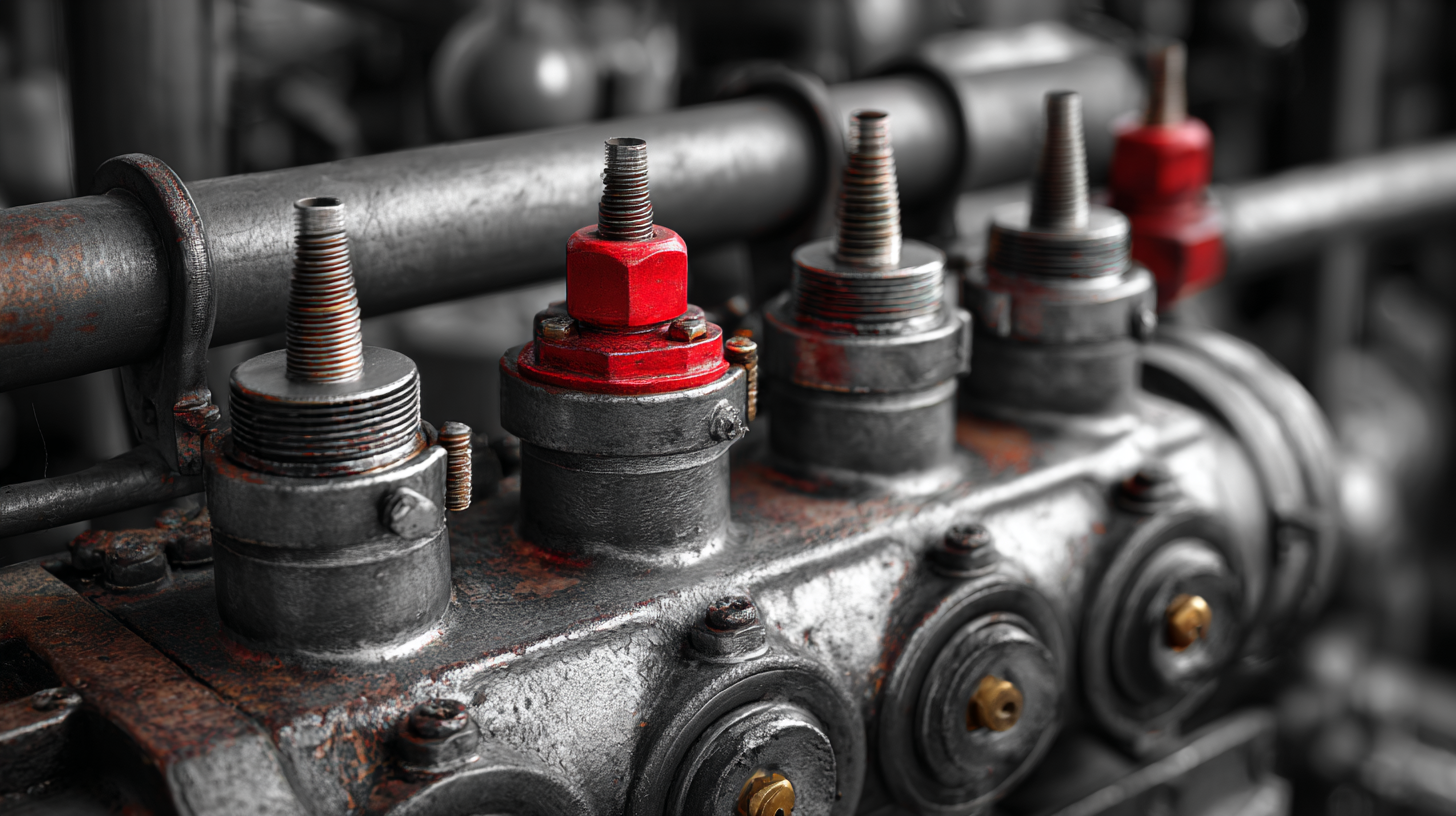

When selecting the best pressure valve for industrial applications, it's crucial to understand the various types available to ensure optimal performance and safety. Pressure relief valves, for instance, are designed to prevent system over-pressurization and protect equipment from potential damage. They automatically release excess pressure when it exceeds a predetermined limit, thereby maintaining safe operating conditions. It's vital to choose a relief valve that is suitable for the specific pressure range and type of fluid involved in the process.

Another common type is the pressure regulating valve, which maintains a consistent downstream pressure regardless of fluctuations in upstream pressure. This function is essential in processes where precise control of pressure is required, such as in chemical manufacturing or water treatment facilities. Additionally, ball valves and gate valves serve distinct purposes in isolating or controlling flow, making them indispensable for various industrial setups. Understanding these distinctions and evaluating the specific requirements of your application will guide you in making an informed decision that aligns with your operational goals.

Selecting the right pressure valve for your industrial system is crucial for efficiency and safety. According to a report by Grand View Research, the global industrial valve market, including pressure valves, is projected to reach $90.5 billion by 2027, highlighting the increasing importance of strategic selection in this area. When choosing a pressure valve, it's vital to consider factors such as the application type, the media being controlled, and the operating pressure range. Different applications, such as oil and gas, chemical processing, and water treatment, demand specific valve types that can withstand unique pressures and chemical exposures.

Another key factor is the materials used in the valve's construction. The resilience and compatibility of materials directly affect the valve's lifespan and performance in various environments. According to a report by Mordor Intelligence, the need for high-performance materials in pressure valves is increasing, with stainless steel and specialty alloys becoming increasingly popular due to their superior corrosion resistance and strength. Evaluating your system's specific requirements and potential pressures can significantly influence operational costs and maintenance needs, making careful selection essential for long-term success.

This chart illustrates the key factors to consider when selecting a pressure valve for industrial systems. Each factor is rated on a scale of 1 to 10, indicating its importance in the selection process. Material quality and pressure rating are deemed the most critical aspects, while size and cost effectiveness are also important but less critical.

When selecting a pressure valve for industrial applications, assessing material compatibility is vital to ensure optimal performance and longevity. Different materials react differently to various fluids and environmental conditions, so understanding the specific characteristics of each material is crucial. For instance, stainless steel is often preferred for its corrosion resistance, while brass might be used for lower-pressure applications due to its cost-effectiveness. Always align the material with the type of fluid—be it corrosive chemicals or high-temperature steam—to avoid premature failure and costly downtime.

Performance standards also play a critical role in the selection process. Evaluation of industry-specific performance standards, such as API, ANSI, and ISO certifications, can guide you in choosing a valve that meets the operational demands of your facility. These standards outline critical benchmarks, including pressure ratings, temperature limits, and flow characteristics, which must be adhered to for safety and efficiency. Do not overlook the importance of documentation that ensures compliance with relevant regulations and promotes the integrity of your operations. By prioritizing both material compatibility and performance standards, you can make informed decisions that enhance system reliability and operational effectiveness.

When selecting a pressure valve for industrial applications, understanding flow rate and pressure requirements is crucial. The flow rate, typically measured in gallons per minute (GPM) or liters per second (L/s), gives insight into how much fluid needs to pass through the valve during operation. Knowing this helps in choosing a valve that can handle the volume without creating turbulence or unnecessary pressure drops. Analyzing the specific system's demands, including peak flow scenarios, allows for precise selection of a valve that sustains optimal performance while minimizing wear and potential failures.

Equally important is assessing the pressure requirements of your system. This involves understanding not just the maximum pressure the valve will encounter but also the working pressure ranges. Using valves rated for higher pressures than needed can lead to unnecessary expenditures, while undervaluing might compromise system safety. Additionally, considering factors like pressure fluctuations and shock loading can guide you toward valves that are specifically designed to handle such situations. By effectively evaluating both flow rate and pressure requirements, one can ensure a wise investment in pressure valves that meet industrial needs efficiently and reliably.

When it comes to selecting a pressure valve for industrial applications, it's crucial to consider not just the specifications but also the brands and manufacturers that stand behind their products. Renowned brands often have a reputation for quality, reliability, and customer service. Leading manufacturers like Emerson, Honeywell, and Parker Hannifin are known for their durable and high-performance pressure valves. Research these companies to find models that suit your specific needs and ensure long-term operational efficiency.

Tip: Before making a decision, check customer reviews and case studies related to the brands you’re considering. Real-world performance feedback can provide insights into the effectiveness and reliability of pressure valves in similar applications to yours.

Another important factor is the warranty and support offered by the manufacturer. Companies such as Swagelok and Bray have been recognized for their excellent customer service and extensive warranties, offering peace of mind for users.

Tip: Don't hesitate to reach out to manufacturers for clarification on product specifications and support options. This proactive approach can lead you to make an informed decision while forming a relationship with suppliers who are ready to assist you.

| Valve Type | Material | Pressure Rating (PSI) | Temperature Range (°F) | Applications |

|---|---|---|---|---|

| Globe Valve | Stainless Steel | 150 | -20 to 400 | Water, Oil, Gas |

| Ball Valve | Brass | 300 | -50 to 200 | Chemical, Water Supply |

| Butterfly Valve | PVC | 150 | 32 to 140 | Water Treatment, HVAC |

| Check Valve | Ductile Iron | 200 | -20 to 300 | Pumping Systems |

| Pressure Relief Valve | Carbon Steel | 600 | -10 to 450 | Oil, Gas, Petrochemicals |