In today's fast-paced world, maximizing efficiency in various systems is crucial for both performance and cost-effectiveness. One essential component that plays a significant role in achieving this is the dual check valve. These innovative devices are designed to prevent backflow while allowing for seamless fluid flow, making them a critical asset in numerous applications, from plumbing to industrial processes. In this blog, we will explore the top strategies for maximizing efficiency with dual check valves, providing practical tips and insights to help you optimize their usage. Whether you are a contractor, engineer, or DIY enthusiast, understanding the key features and benefits of dual check valves will enable you to make informed decisions that enhance system reliability and operational efficiency. Join us as we delve into the best practices for harnessing the full potential of these vital components.

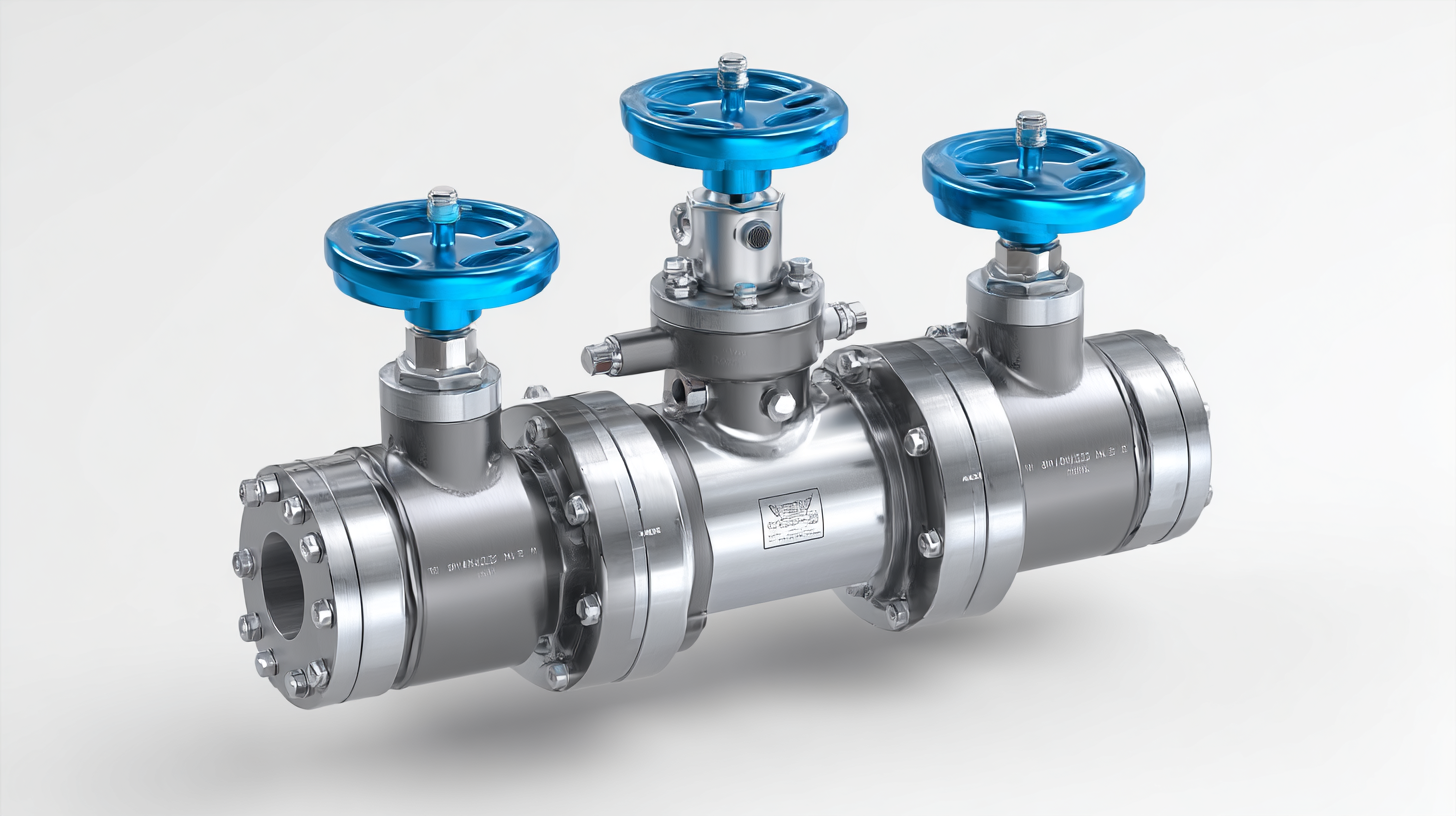

Dual check valves play a crucial role in various plumbing and industrial applications, ensuring that fluid flows in the correct direction while preventing backflow. Their functionality lies in the design, which incorporates two independently acting check valves. This redundancy not only enhances reliability but also increases system efficiency by minimizing the potential for contamination and pressure loss. Understanding the importance of dual check valves can lead to better system performance and longevity.

One key tip for maximizing efficiency with dual check valves is to ensure proper sizing. Selecting the right valve size for your application can prevent unnecessary pressure drops and inefficiencies in fluid transfer. Additionally, regular maintenance is essential; inspecting and cleaning the valves periodically can help detect any wear or blockages, ensuring they function smoothly.

Another important consideration is the installation location. Positioning dual check valves near potential sources of contamination can significantly reduce the risk of backflow. Make sure to follow the manufacturer's guidelines for installation to avoid any operational issues. Through these strategies, you can enhance the performance and lifespan of your dual check valves, leading to improved system efficiency.

Implementing dual check valves in fluid systems can significantly enhance operational efficiency and safety. According to the Hydraulic Institute, systems employing dual check valves can reduce water hammer effects by up to 50%, which is crucial in minimizing wear and tear on piping infrastructure. This not only prolongs the lifespan of equipment but also decreases maintenance costs. The ability of dual check valves to prevent backflow ensures that systems operate smoothly without the risk of contamination, adding a layer of safety that can be essential in both residential and industrial applications.

Furthermore, a recent report by the American Society of Mechanical Engineers indicates that systems utilizing dual check valves have shown a reduction in energy consumption by 15% due to optimized flow management. By maintaining consistent pressure levels, these valves facilitate better performance of pumps and other machinery. This benefit is compounded by the ease of installation and maintenance, allowing for quicker adjustments and modifications to meet system demands. As industries strive for sustainability and cost-effectiveness, dual check valves emerge as a strategic asset in achieving these goals.

This chart illustrates the various key benefits of implementing dual check valves in a system, showcasing areas such as energy savings, operational cost reduction, and overall maintenance efficiency. These factors play a critical role in maximizing system efficiency.

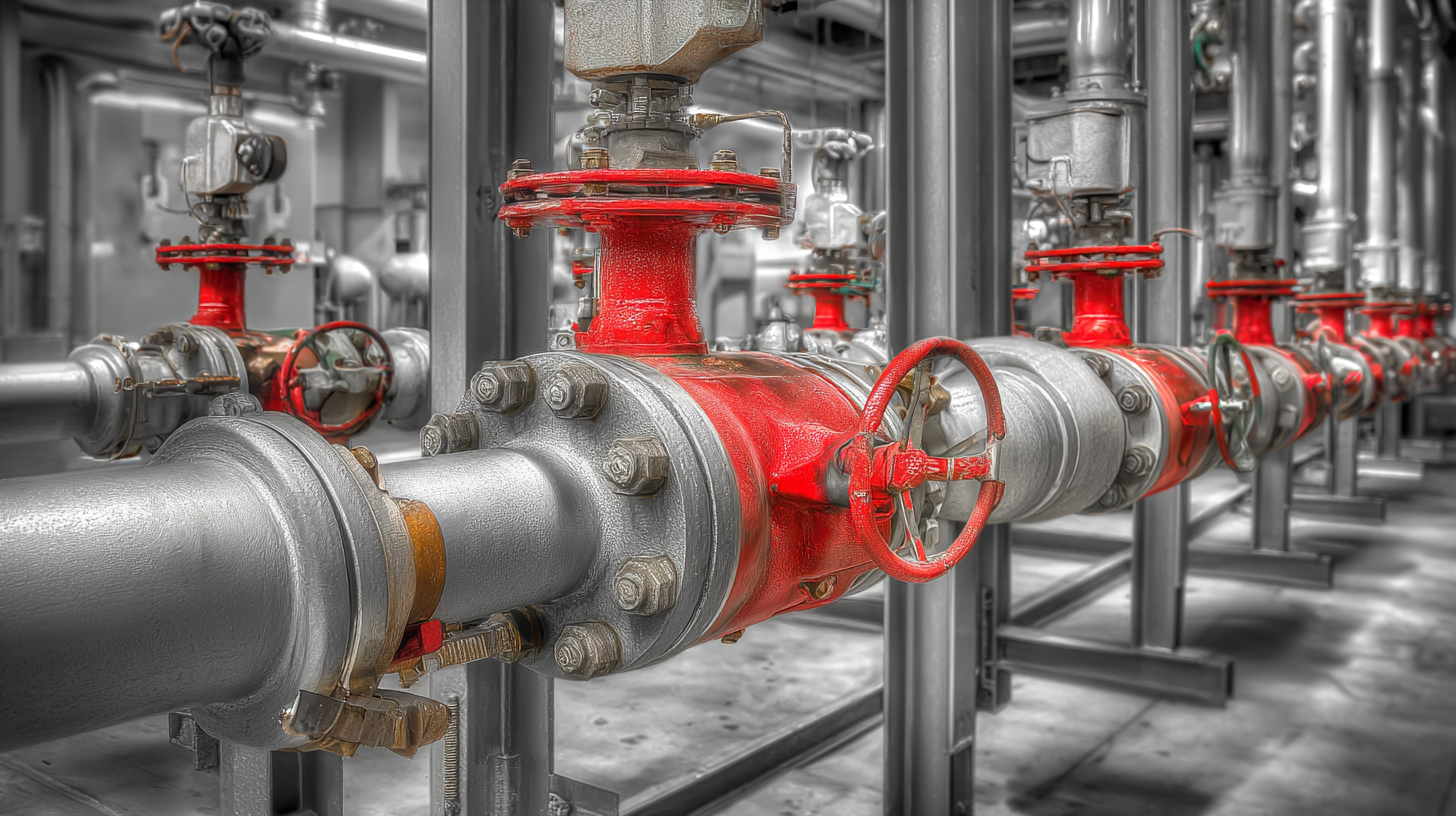

When it comes to enhancing efficiency in plumbing systems, the installation of dual check valves plays a crucial role. To ensure optimal performance, it is essential to follow best practices during installation. Firstly, selecting the right location is vital. Dual check valves should be installed in areas where they can easily be accessed for maintenance and inspection, typically near the water supply source. This positioning not only facilitates regular checks but also minimizes the risk of potential backflow issues that could affect the entire system.

Additionally, proper orientation and sealing are critical components of effective installation. Dual check valves should be positioned in the correct flow direction, as indicated by the manufacturer’s guidelines, to guarantee that they operate correctly. Using high-quality gaskets or sealants can prevent leaks and ensure a tight fit. It's also advisable to install isolation valves alongside dual check valves. This allows for easy maintenance without disrupting the entire system, thereby further optimizing efficiency. Implementing these best practices will help in maximizing the effectiveness of dual check valves, ultimately leading to improved flow rates and reduced energy consumption in your plumbing setup.

| Strategy | Description | Benefits | Best Practices |

|---|---|---|---|

| Proper Sizing | Ensure dual check valves are sized appropriately for the application. | Improves flow efficiency and reduces wear. | Consult manufacturer specifications for sizing ratios. |

| Regular Maintenance | Conduct routine inspections and maintenance checks. | Prolongs valve life and maintains optimal performance. | Set a maintenance schedule based on usage levels. |

| Installation Orientation | Install valves in the correct orientation for optimal function. | Prevents backflow and enhances system integrity. | Follow installation guidelines for directional flow. |

| Use of Clean Water | Ensure that the water used is free from debris and contaminants. | Reduces clogging and extends valve operational life. | Install filtration systems upstream if necessary. |

| System Design Review | Conduct a review of the overall system design. | Identifies potential efficiency improvements. | Engage with system engineers for optimized layouts. |

When utilizing dual check valves, avoiding common pitfalls can significantly enhance their efficiency and prolong their lifespan. One of the most frequent mistakes is improper installation, which can lead to backflow issues and increased wear on the system. According to industry reports, improper alignment during installation can reduce the valve's effectiveness by nearly 30%, underscoring the need for precision in positioning and securing check valves.

Another key error to watch out for is the neglect of routine maintenance. Many operators overlook the importance of regular inspection and cleaning, which can result in blockages and reduced flow rates. Data indicates that systems with monthly maintenance checks experienced a 20% longer operational lifespan compared to those that were ignored for lengthy periods. Additionally, it's essential to ensure that the selected dual check valves are appropriate for the specific application. Using valves that are not rated for the pressure or type of fluid can lead to catastrophic failures, akin to the engine malfunctions seen in marine applications when proper precautions are missed. By focusing on these areas, operators can enhance the performance and reliability of their dual check valves while minimizing costly downtime.

Routine maintenance of dual check valves is crucial for ensuring their optimal performance and longevity. According to a report by the American Society of Mechanical Engineers, improper maintenance can lead to a significant increase in system failures—up to 25% more downtime in industrial applications. Regular inspections, at least bi-annually, can help in identifying wear and tear, allowing for proactive repairs or replacements before a complete failure occurs.

Additionally, cleaning the valves and surrounding components is essential to prevent debris buildup that can impede flow and efficiency. The Hydraulic Institute suggests that maintaining clean valve seats can improve flow efficiency by up to 15%, which directly impacts the overall energy consumption of fluid systems. Operators should also check seals and connections for signs of leaks, as even small leaks can result in significant losses over time. By implementing these routine maintenance tips, facilities can ensure their dual check valves operate at peak efficiency, ultimately saving costs and minimizing operational disruptions.