In the ever-evolving landscape of industrial processes, the selection of the right industrial valves is critical to ensuring operational efficiency and safety. According to a recent report by MarketsandMarkets, the global industrial valves market was valued at approximately $70 billion in 2021, and it is projected to reach $100 billion by 2026, growing at a CAGR of 7.2%. This increase underscores the essential role that industrial valves play across various sectors, including oil and gas, water and wastewater treatment, and chemical processing.

With numerous types available—ranging from ball valves to gate valves and butterfly valves—understanding the specific requirements of your system is vital. The right choice can minimize downtime, enhance performance, and contribute to the overall robustness of your industrial operations. This blog will delve into different types of industrial valves, offering insights to help you make informed decisions for your system needs.

When selecting the right type of industrial valve for your system, understanding the key features and applications of different valve types is essential. Gate valves, for instance, are ideal for on/off applications where minimal pressure drop is required. They feature a wedge-shaped disk that moves perpendicular to the flow, ensuring a tight seal when fully closed. However, they are not suitable for throttling applications, as partial opening can lead to damage or inefficiency.

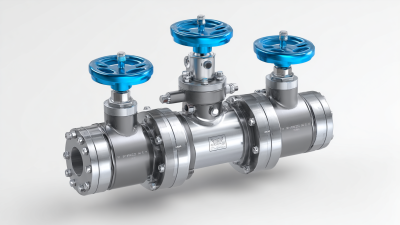

On the other hand, globe valves are designed for throttling and flow regulation, thanks to their linear motion mechanism that allows for precise control. These valves have a spherical body with an internal baffle that directs fluid flow, making them ideal for applications requiring frequent adjustments. Similarly, ball valves provide quick shut-off capabilities due to their quarter-turn operation and are widely used in pipelines for their reliability and low torque requirements. Each valve type serves specific roles in industrial systems, making it crucial to align your choice with the functional requirements and operational conditions of your application.

When choosing the right valve for your system, various factors must be taken into account to ensure optimal performance and efficiency. The type of valve you select can directly affect the overall functionality of your system. For instance, in the automotive sector, the valve market is projected to reach a size of approximately $40 billion by 2025, exhibiting a compound annual growth rate (CAGR) of around 5% from 2020 to 2025. This growth underscores the importance of specific valve characteristics tailored to unique applications, such as engine valves for performance and efficiency, A/C valves for climate control, and thermostat valves for temperature regulation.

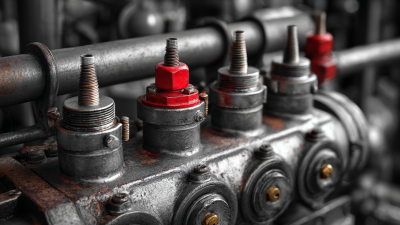

Additionally, considerations like material selection, pressure and temperature ratings, and actuation methods play a crucial role in valve performance. According to industry research, about 40% of valve failures are attributed to improper material selection based on operating conditions. Therefore, understanding your system's requirements—whether it be chemical compatibility or temperature extremes—is essential in making a well-informed choice. As valves are pivotal components in ensuring system integrity and safety, investing time in this decision-making process will ultimately enhance performance and reduce maintenance costs.

When selecting industrial valves for your system, understanding the pros and cons of common valve types is crucial. Starting with the globe valve, its design allows for excellent throttling capabilities, making it suitable for flow regulation. However, the disadvantage lies in its relatively high pressure drop due to the flow path, which can be inefficient in high-capacity systems.

Another popular choice is the ball valve, known for its quick operation and minimal flow resistance. This type is ideal for on/off control, offering robust sealing that reduces leakage. Nonetheless, ball valves may not be suitable for throttling applications as they can experience erosion and damage if partially opened for an extended period.

Lastly, gate valves provide an unobstructed flow path, making them perfect for high-pressure applications. Yet, they lack the flexibility for flow regulation and can be slow to operate, which could hinder system responsiveness. Each valve type has particular strengths and weaknesses, and understanding these can significantly influence the performance and efficiency of your industrial system.

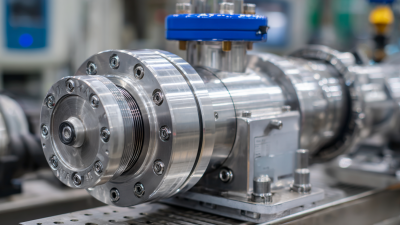

Industrial valves play a crucial role across a multitude of industries, each with specific requirements that dictate the choice of valve type. In the oil and gas sector, for example, valves provide essential functionalities such as flow control and pressure regulation in pipelines. High-pressure ball valves are commonly utilized here because their robust design ensures safety and reliability in managing the volatile nature of these substances. Similarly, in the chemical industry, diaphragm valves are favored for their ability to handle corrosive materials, allowing for safe and efficient processes.

Industrial valves play a crucial role across a multitude of industries, each with specific requirements that dictate the choice of valve type. In the oil and gas sector, for example, valves provide essential functionalities such as flow control and pressure regulation in pipelines. High-pressure ball valves are commonly utilized here because their robust design ensures safety and reliability in managing the volatile nature of these substances. Similarly, in the chemical industry, diaphragm valves are favored for their ability to handle corrosive materials, allowing for safe and efficient processes.

In the water treatment and wastewater management industries, reliable valves are vital for ensuring the proper flow and treatment of water. Gate valves are often employed in this sector due to their straightforward operation and tight sealing capabilities, essential for minimizing leaks and ensuring operational efficiency. Furthermore, in the food and beverage industry, sanitary valves are indispensable for maintaining hygiene standards while allowing for effective flow control. Butterfly valves, which offer quick operation and low torque requirements, are commonly used here for their ability to handle various liquid viscosity levels without compromising safety or cleanliness. Each application underscores the importance of selecting the right valve type tailored to the specific demands of the industry.

Maintaining industrial valves is crucial for ensuring optimal performance and longevity of your system. Regular maintenance can prevent unexpected failures and costly downtime. One essential tip is to develop a routine inspection schedule. Inspect for leaks, wear, and corrosion, paying special attention to seals and gaskets, as these components are often the most vulnerable.

Another important practice is to keep valves clean and free from debris. Accumulated dirt and deposits can hinder the valve's functionality, leading to inefficient operation. Utilize appropriate cleaning materials and techniques to avoid damaging the valve surfaces. After cleaning, make sure to lubricate moving parts as necessary to maintain seamless operation.

Finally, it's vital to stay updated with the manufacturer’s maintenance guidelines. Following recommended procedures can significantly enhance the performance of your valves. Documentation of maintenance activities also helps in tracking performance trends and identifying potential issues before they escalate. Adopting these maintenance best practices will help ensure your industrial valves operate efficiently and reliably.