In the realm of industrial operations, the significance of maintaining optimal pressure levels cannot be overstated, and a pressure control valve stands at the forefront of achieving this goal. Understanding industry standards for pressure control valves is crucial for ensuring safety, efficiency, and reliability in various applications. This blog will explore the best practices for selecting and implementing pressure control valves, highlighting essential tips to navigate common challenges faced by engineers and operators alike. From troubleshooting valve-related issues to optimizing performance, this comprehensive guide aims to equip professionals with the knowledge needed to enhance their systems. As industries continue to evolve, staying informed about the latest standards and innovations in pressure control technology is imperative for driving success and minimizing disruptions.

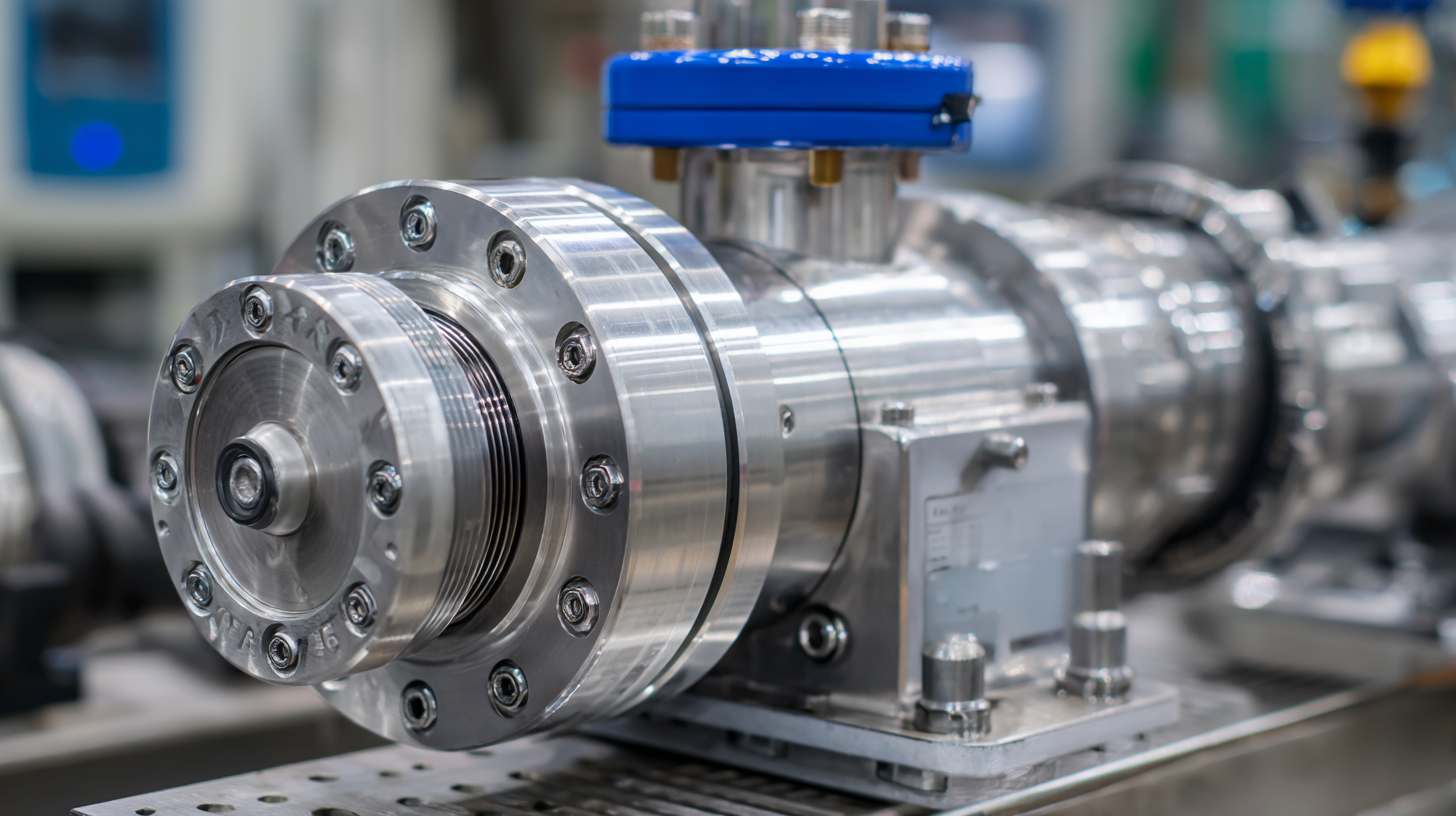

In various industries, particularly those driven by rapid technological advancements, high-quality pressure control valves play a crucial role in maintaining operational efficiency and safety. Essential features of these valves include precise pressure regulation, durable construction, and reliable performance under varying conditions. Industries such as oil and gas, pharmaceuticals, and semiconductor manufacturing are increasingly focused on these attributes to meet stringent operational requirements and regulatory standards.

As the semiconductor industry continues to grow, with forecasts indicating a substantial increase in vacuum valve market size from $1.37 billion in 2023 to $2.8 billion by 2031, the demand for robust pressure control solutions is on the rise. Companies are urged to invest in advanced pressure control valves that can withstand high pressures and provide exceptional control. This demand highlights the importance of selecting valves that not only meet industry standards but also offer innovative features that enhance system reliability and efficiency. As industries evolve, understanding the key characteristics of high-quality pressure control valves becomes essential for ensuring optimal performance and addressing common operational challenges.

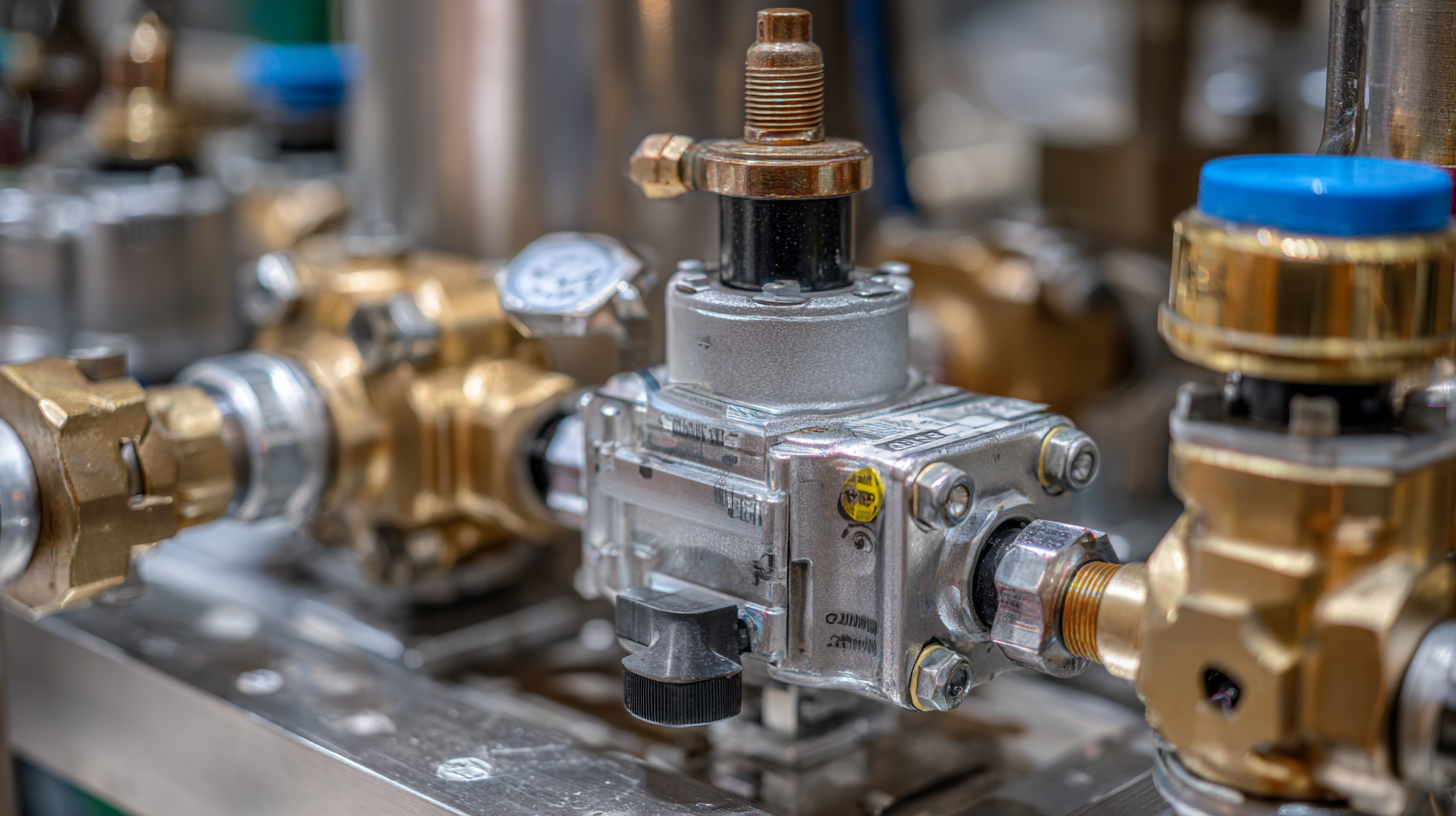

Pressure control valves are vital components in various industrial applications, ensuring optimal system performance and safety. However, malfunctions can lead to significant operational issues. Common symptoms of pressure control valve malfunctions include erratic pressure readings, fluctuating flow rates, and unexpected equipment shutdowns. According to a 2021 report by the International Society of Automation, approximately 30% of pressure control valve failures are attributed to improper maintenance practices, highlighting the importance of regular inspections and timely repairs.

One prevalent type of malfunction is seat leakage, which can result in an inability to maintain the desired pressure levels. Symptoms include audible hissing sounds or visible fluid seepage, indicating that the valve is not sealing correctly. A study published in the Journal of Pressure Vessel Technology revealed that nearly 25% of pressure-related safety incidents stem from seat leaks. Another common issue is actuator failure, which can occur due to worn components or inadequate power supply. In such cases, the valve may become stuck or fail to respond to control signals, creating hazardous conditions. Monitoring and addressing these symptoms promptly are crucial for maintaining the efficiency and safety of industrial systems.

| Valve Type | Common Malfunctions | Symptoms | Solutions |

|---|---|---|---|

| Spring-Loaded Pressure Relief Valve | Sticking or leakage | Unusual noise or pressure fluctuations | Inspect and clean the valve; replace seat or spring if necessary |

| Pilot-Operated Relief Valve | Failure to open or close | Constant high-pressure readings | Check the pilot pressure, clean the valve, or replace seals |

| Pressure Regulating Valve | Inconsistent pressure output | Pressure spikes and drops | Adjust set pressure or replace worn components |

| Electronic Pressure Control Valve | Electrical failure | Erratic valve operation or failure to respond | Check wiring, replace faulty sensors or actuators |

| Ball Valve | Seat wear or internal leaks | Increased leakage or inability to isolate fluid | Replace the ball or seals, or consider full valve replacement |

Inadequate pressure control can severely impact system efficiency and safety, particularly in complex energy systems such as hydrogen production and renewable energy integration. When pressure control valves fail to maintain optimal pressure levels, it can lead to hazardous conditions, inefficiencies, and significant operational costs. For instance, in hydrogen energy systems where pressure management is crucial, improper regulation can result in energy losses and safety risks, making it imperative to adopt industry standards for pressure control solutions.

Moreover, as energy systems increasingly incorporate advanced technologies like artificial intelligence and smart grids, the importance of robust pressure control becomes even more pronounced. These technologies rely on precise pressure regulation to enhance their functionality and performance. Without effective pressure control mechanisms, the performance of systems integrating renewable energy sources could be compromised, affecting the reliability and safety of operations. Therefore, addressing common issues related to pressure control valves not only ensures system efficiency but also plays a vital role in the transition toward safer and more sustainable energy solutions.

Maintaining pressure control valves is crucial for the efficient and safe operation of industrial systems. According to a report by the Fluid Controls Institute, regular maintenance can improve valve lifespan by 30% and reduce operational costs by up to 25%. This highlights the importance of adopting best practices such as routine inspections, proper calibration, and prompt repairs to prevent common issues such as leaks or pressure drops. Implementing a preventive maintenance program not only ensures the reliability of the valves but also enhances overall system performance.

Another essential practice is using high-quality materials and components, as specified by the American Society of Mechanical Engineers (ASME). Their guidelines emphasize that the choice of materials directly impacts the durability and functionality of pressure control valves. Regular training for the maintenance staff on the latest technologies and industry standards can further aid in recognizing early signs of wear and tear, which allows for timely interventions. By incorporating these best practices, industries can mitigate the risk of valve failures and associated downtime, ensuring a more efficient and safe working environment.

The landscape of pressure control valves is evolving rapidly with the advent of emerging technologies and innovative designs. Modern pressure control valves are now equipped with advanced materials that enhance their durability and functionality, enabling them to operate effectively under extreme conditions. Digital technologies, such as IoT sensors and smart actuators, have also begun to play a crucial role in real-time monitoring and automated adjustments, providing greater precision in pressure regulation. These innovations not only improve operational efficiency but also significantly reduce the risk of failures and leaks, which can lead to costly downtimes and safety hazards.

Moreover, the integration of artificial intelligence in pressure control valve systems presents exciting possibilities for predictive maintenance. By analyzing operational data, AI can identify patterns that signal potential failures before they occur, allowing for timely interventions. Additionally, new design approaches, such as modular systems, offer enhanced flexibility and ease of maintenance. These advancements ensure that industries can adapt swiftly to fluctuating demands while maintaining safety and compliance with evolving industry standards.

As technology continues to progress, the future of pressure control valves looks promising, paving the way for more reliable and efficient industrial processes.